Written By: Robert E. Sheriff, MS, CIH, CSP, President January 15, 2020

If you need assistance with Local Exhaust Ventilation as discussed in this article, call us at 973-366-4660 or e-mail us at info@atlenv.com for details and a free estimate.

Options to Protect a Worker from Exposure to Air Contaminants

There are a variety of ways to protect a worker from exposure to an air contaminant. The best option is to eliminate contaminants!! Often this is not possible!

The second option is to isolate the process from the worker (Enclosure) or isolate the worker from the process (Control Room or Booth).

The third option – and often the most practical approach – is to exhaust the contaminant at the point of generation AND before it gets into the worker’s breathing zone or in the workroom air. This process is often referred to as LOCAL EXHAUST VENTILATION.

There is a vast variety of methods to accomplish this depending upon the characteristics of the contaminant to be captured.

Some Examples:

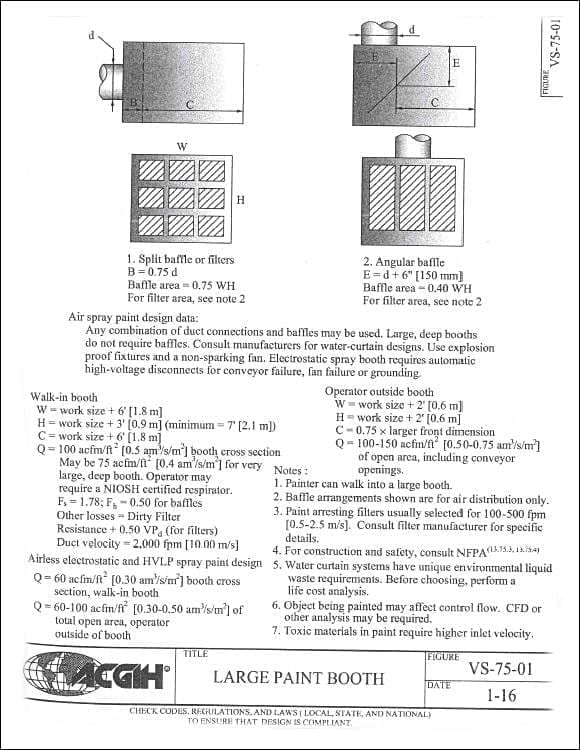

Painting:

Construct a paint spray booth such that the operation is outside the booth and air flows into the booth drawing the paint overspray away from the worker’s breathing zone.

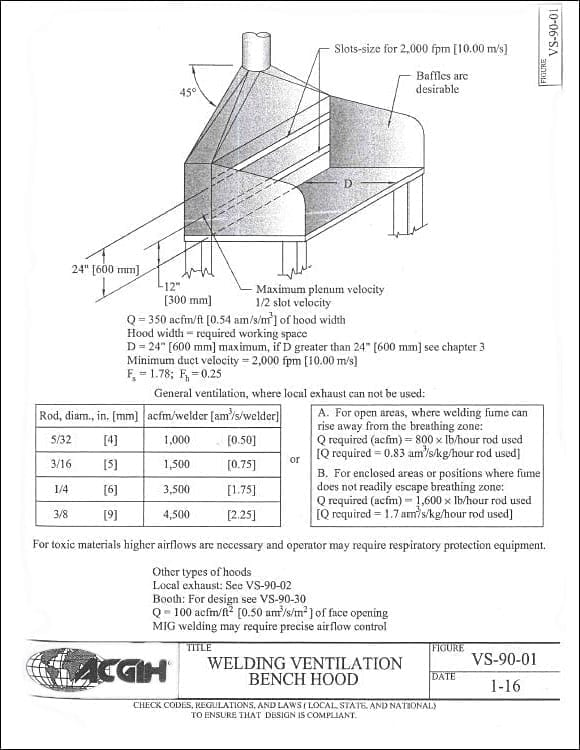

Welding: Construct an exhaust hood near the welding point to draw the welding fumes away from the welder and out of the building’s air. Where the weld is not on a stationary part, a flexible exhaust that can be moved near the welding point can be very effective—BUT BEWARE NOT to have the exhaust so close to the welding point that interferes with the inert gas shield around the weld, resulting in defective (oxidized) welds.

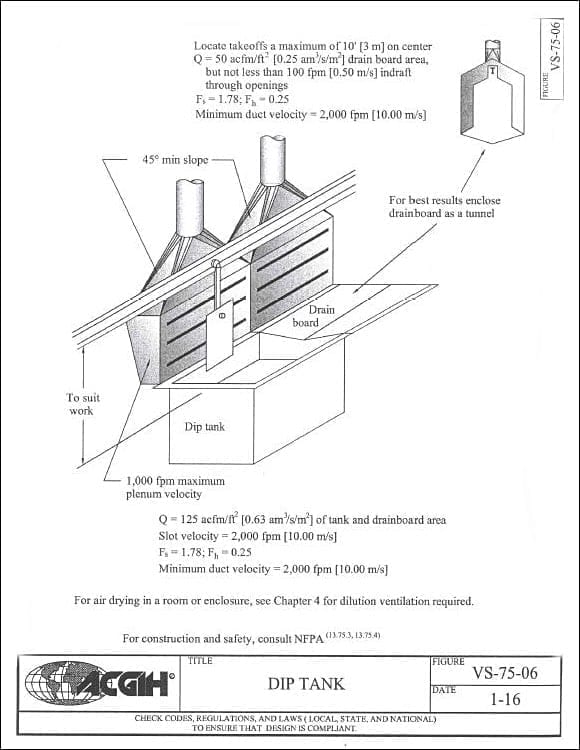

Plating Tanks: Install a backdraft hood (behind the tank away from the worker) or side draft hood (slot exhaust on either side of the tank to capture the fumes).

NOTE: That the exhaust must be carefully designed to achieve the proper capture velocity depending upon the 1. Size of the tanks, 2. Temperature updraft, 3. Raising and lowering the parts.

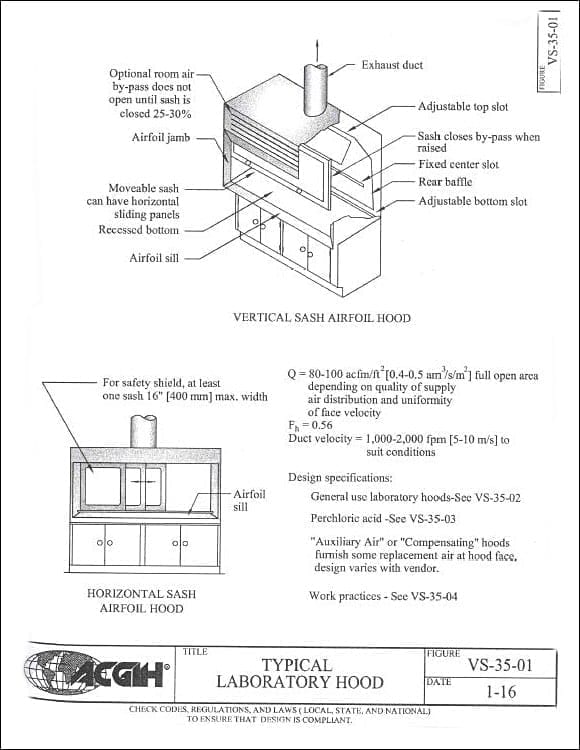

Laboratories: Install hoods with sufficient exhaust air volume to contain the contaminants inside the hood while the Lab Technician is outside the hood.

There are an endless variety of local exhaust ventilation configurations depending upon the contaminant, the worker’s position, and the processes involved. An excellent source of detailed information on designing, operating and maintaining local exhaust ventilation systems can be found in Industrial Ventilation: A Manual of Recommended Practice for Design (29th Edition) by the American Conference of Governmental Industrial Hygienists (ACGIH). Also: Industrial Ventilation: A Manual of Recommended Practice for Operations and Maintenance (2nd Edition).

FINAL NOTE: Local exhaust ventilation system can only work effectively if there is sufficient supply make-up air to prevent a negative pressure condition.

We have the capability to design new systems and update existing systems including airflow measurements and operating efficiency. Contact us for more information at 973-366-4660 or info@atlenv.com. For more information on ventilation, go to our website at www.atlenv.com.

Our primary service areas are New Jersey NJ, New York NY, (New York City), Pennsylvania PA, Connecticut CT, Delaware DE, Massachusetts, (Boston) MA, Rhode Island RI, Washington DC, Wisconsin WI, Maryland MD, Michigan MI, Illinois (Chicago) IL, Virginia VA, Indiana IN, Georgia (Atlanta) GA, Alabama AL, North Carolina NC, South Carolina SC, Tennessee TN, Texas (Dallas, Ft Worth) TX, Oklahoma OK, DC, Arkansas AR, Florida FL. We can service most other areas of the U.S. but with some added travel charges.