If you need paint spray booth testing assistance as discussed in this article, call us at 973-366-4660 or e-mail us at info@atlenv.com for details and a free estimate.

Written By: Robert E. Sheriff, MS, CIH, CSP, President

November 13, 2020

How To Test a Paint Spray Booth

There are two basic approaches to testing a paint spray booth for proper operation:

- Testing airflow to confirm whether adequate airflow will keep the paint emissions from getting into the paint spray operator’s breathing zone.

- Testing worker exposure to spray paint emissions by sampling the worker/operator.

In most cases, it is necessary to test both air flow AND worker exposure to the paint components.

I. Testing Air Flow – Face Velocity

The amount of air flowing into the paint booth must be sufficient to overcome the overspray from the spray gun.

The first set of tests should be to test the FACE VELOCITY of the booth.

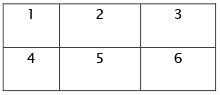

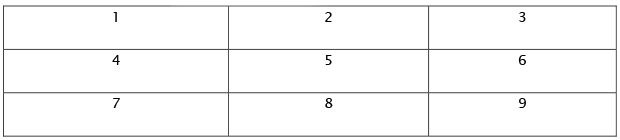

That is: using a velometer, thermo anemometer, vane anemometer, or other airflow measuring device to test the airflow at the face of the spray booth. It is best to set up an imaginary grid across the booth’s face.

(Small Booth-At Least 6 Grids)

(Large Booth-9 or More Grids)

Take airflow measurements at the center of each grid—then average the airflow from all grids.

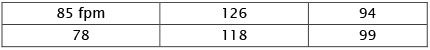

Example:

Average: 100 units feet per minute (fpm) = “V” (Velocity).

In most cases, 100 fpm is sufficient to capture the paint emissions—as long as the spray is directed inward toward the exhaust (rear) of the booth.

The total exhaust volume can be calculated using the formula:

Q = AV where A is the area of the booth (length x height) and V is the measured air velocity in feet per minute-(fpm) where Q = air volume in cubic feet per minute (cfm).

Q = AV where Q = air volume in cfm.

A = area of the opening in ft2.

V = velocity in fpm.

II. Testing Air Flow – Capture Velocity

However: The real measurement of the air movement that is effective at containing the paint spray is the CAPTURE VELOCITY: that is the airflow at the point where the paint spray is actually emitted or at the operator’s breathing zone. Ideally, that is at the booth face—the FACE VELOCITY.

Sometimes the spray emissions point is outside the booth thus, the CAPTURE VELOCITY must be taken from that point.

If 100 fpm is what is desired to control the spray paint emissions, then that is the airflow needed as the CAPTURE VELOCITY whether outside the booth or inside the booth—more precisely in the painter’s breathing zone!

As expected, if the capture point is outside the booth, then consideration must be given to the distance outside the booth where the appropriate capture velocity is needed. That changes the formula from:

Q = AV to:

Q = V (10 x 2 + A) where X = distance from booth face to capture point-(in ft).

NOTE: The further the capture point is from the booth’s face, the greater the air volume to capture the paint spray emissions.

BUT WAIT!!!

III. Testing Worker Exposure For Effective Booth Air Flow

The real measurement to establish the effectiveness of the airflow is whether the paint spray operator is protected from the paint spray solvents and particulates.

If the paint spray operator’s exposure is acceptable, (OSHA Compliant or otherwise within acceptable exposure limits), then the spray booth is performing as needed and intended—regardless of the airflow!! Thus, the true test of adequate airflow is monitoring the worker using proper industrial hygiene monitoring methods.

If the worker sampling/testing indicates an overexposure, then the airflow measurements are important by defining the current airflow so that it can be increased appropriately and thus result in proper capture velocity—and worker protection.

Too often decisions are made on the adequacy of airflow/air volume without monitoring the worker’s exposure to the paint emissions.

The ideal situation is to monitor the worker for the contents of the paint (consult the Safety Data Sheets-SDS) and measure the Capture Velocity/Face Velocity and Exhaust Volume (Q=AV) of the booth at the same time.

We have the ability to monitor workers’ exposures and measure the ventilation systems. If you need assistance, contact us at info@atlenv.com or 973-366-4660.

References

Industrial Ventilation Manual, Volume I-Design, American Conference of Governmental Industrial Hygienists (ACGIH), 29th Edition, 2016.

Our primary service areas for spray booth testing are New Jersey NJ, New York NY, (New York City), Pennsylvania PA, Connecticut CT, Delaware DE, Massachusetts, (Boston) MA, Rhode Island RI, Washington DC, Wisconsin WI, Maryland MD, Michigan MI, Illinois (Chicago) IL, Virginia VA, Indiana IN, Georgia (Atlanta) GA, Alabama AL, North Carolina NC, South Carolina SC, Tennessee TN, Texas (Dallas, Ft Worth) TX, Oklahoma OK, DC, Arkansas AR, Florida FL. We can service most other areas of the U.S. but with some added travel charges.