If you need an evaluation of worker exposure to Beryllium discussed in this article, call us at 973-366-4660 or e-mail us at info@atlenv.com for details and a free estimate.

Written By: Robert E. Sheriff, MS, CIH, CSP, President

February 20, 2020

Worker Exposure to Beryllium Health Hazards – New Regulations Are Here!

Recently OSHA has put new Beryllium Regulations in effect to lower worker exposure levels. Based on information on the health hazards of worker Beryllium exposure, OSHA has lowered the allowable exposure level by a factor of 10—from 2 ug/m3 to 0.2 ug/m3—and create a separate standard for Beryllium (29 CFR 1910.1024).

The OSHA Beryllium Regulation (29CFR1910.1024) went into effect on January 6, 2017, with a compliance date of May 20, 2018.

There are separate regulations for General Industry (29CFR1910.1024), Construction (29CFR1926.1124) and Shipyards (29CFR1915.1024).

There are a variety of ways an individual may be exposed to Beryllium or Beryllium containing compounds.

What is Beryllium?

Beryllium is a metal that is strong, lightweight and conducts electricity. By just those criteria, you can see that it could have many modern-day uses.

Because it is relatively rare and difficult to separate from the surrounding rock, Beryllium is expensive and available in limited quantity. At the same time, it has many uses including:

Where Beryllium Is Used

Aerospace,

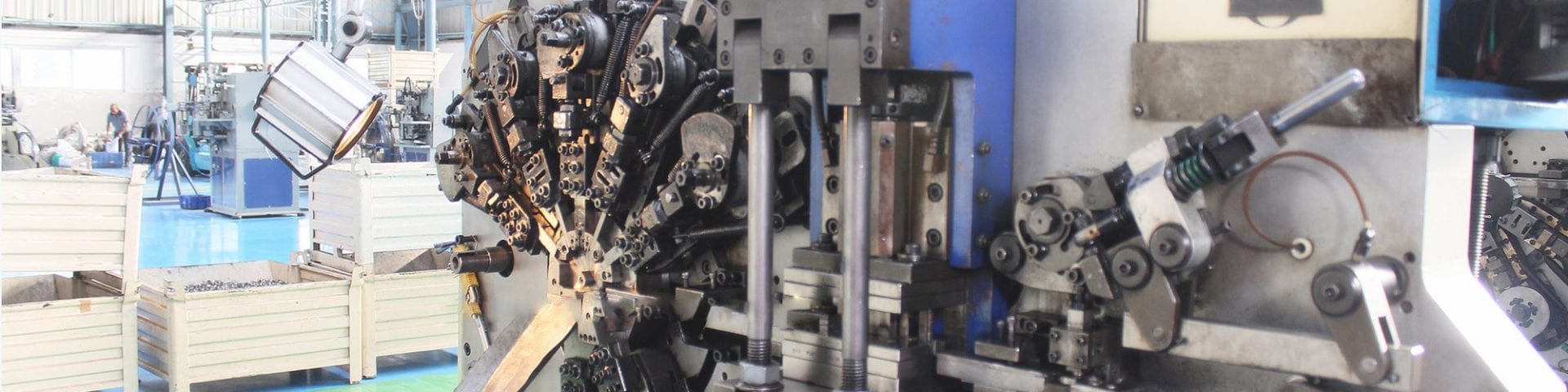

Automotive parts,

Computes,

Dental supplies,

Prosthetics,

Electronics,

Ceramics,

Metal recycling,

Instrument recycling,

Electronics recycling,

Beryl ore mining,

Nuclear weapons,

Precision machine parts,

Welding of electronic and precision parts.

Each of these uses presents the potential for beryllium exposures to workers mining, refining, molding, product development, manufacturing, usage and after life such as recycling or disposal. (Thankfully it has yet to be shown to be a hazard to golfers since it is used in new lightweight golf clubs! Yours truly) is breathing a sigh of relief!!

Some of the more significant beryllium exposures seem to be in casting and processing of Beryllium Copper and Beryllium Aluminum Alloys. This also includes deburring, heat treating, plating, polishing, cleaning, soldering, and assembly of components.

Production of other Beryllium products also presents exposure potential that may exceed the proposed OSHA PEL of 0.2 ug/m3. This can include casting, machining, and assembly of electronic components, plastic molding, dental plates manufacturing, sporting equipment (those golf clubs!), and nuclear shielding applications. Usage of these Beryllium containing products and components usually do not present any significant exposure potential to the end-user unless there is substantial friction or heat generation involved. (Usually not the case with my golf clubs).

A Cancer-Causing Substance

The diseases caused by exposure to Beryllium are significant and it is recognized that the current OSHA PEL of 2 ug/m3 is not sufficiently protective of the worker. Chronic Beryllium Disease (CBD) previously known as Berylliosis is an allergic sensitization reacts primarily in the lungs but it can also damage the liver, kidneys, nervous system and lymphatics. The consequences can be disabling and potentially fatal. The International Agency for Research on Cancer (IARC) and ACGIH now list Beryllium as a cancer-causing substance.

Acute Beryllium Disease

There are also acute effects of exposure to Beryllium including skin sensitization, absorption through cuts, and damage to the eyes. Heavy exposure over a short period of time may result in acute Beryllium disease which affects the lungs with a condition similar to bronchitis or pneumonia.

Sampling/Testing

Initial and regular monitoring of workers who may be exposed to Beryllium is an essential requirement of the new standard. Personnel sampling/testing for Beryllium is not complex. It usually involves attaching a portable air sampling/testing device to the employee for a work shift and comparing the results to the OSHA PEL.

Such sampling/testing should be done by a suitably qualified individual such as an industrial hygienist who can perform the testing, evaluate the work activity, interpret the results, and provide guidance and recommendations where corrective measures are necessary to reduce exposure levels.

The new OSHA Standard for Beryllium 29 CFR 1910.1024 has very specific requirements for testing, program development, protective measures, biological monitoring, training, and recordkeeping. Further details can readily be obtained from the OSHA website at .osha.gov.

Atlantic Environmental, Inc. is familiar with Beryllium health hazards and the requirements for Beryllium compliance and has qualified individuals to be of assistance to any organization that deals with Beryllium.

References:

http://www.osha.gov-search for“Beryllium”

http://www.state.nj.us/health/eoh/rtkweb/documents/fs/0222.pdf

www.ncbi.nlm.nih.gov/pmc/articles/PMC2847329/

https://www.atsdr.cdc.gov/scem/scem.asp?csem=5&po=6

For more information contact Atlantic Environmental.

Our primary service areas are New Jersey NJ, New York NY, (New York City), Pennsylvania PA, Connecticut CT, Delaware DE, Massachusetts, (Boston) MA, Rhode Island RI, Washington DC, Wisconsin WI, Maryland MD, Michigan MI, Illinois (Chicago) IL, Virginia VA, Indiana IN, Georgia (Atlanta) GA, Alabama AL, North Carolina NC, South Carolina SC, Tennessee TN, Texas (Dallas, Ft Worth) TX, Oklahoma OK, DC, Arkansas AR, Florida FL. We can service most other areas of the U.S. but with some added travel charges.